Cuisse

Ohio University - 2019

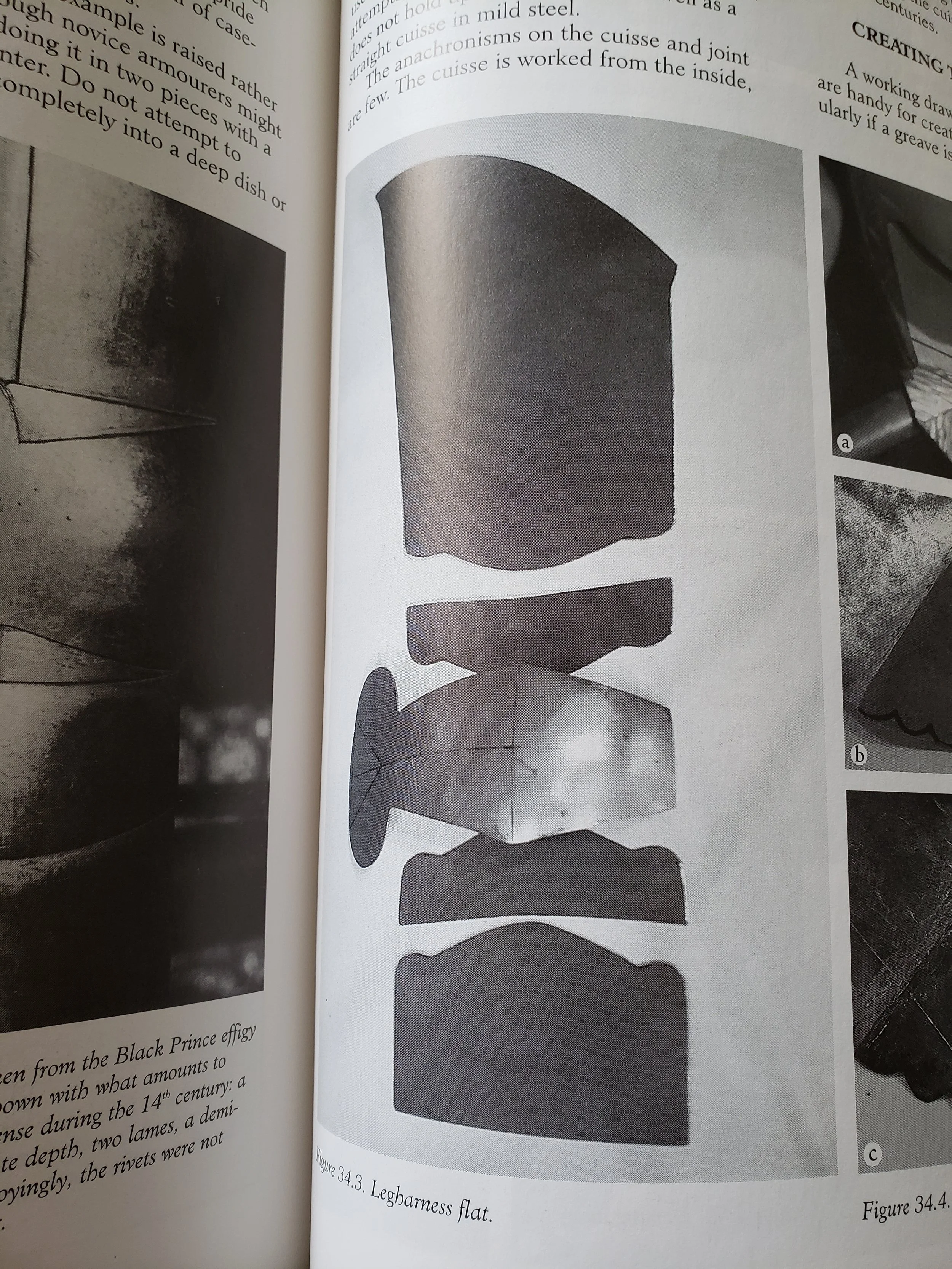

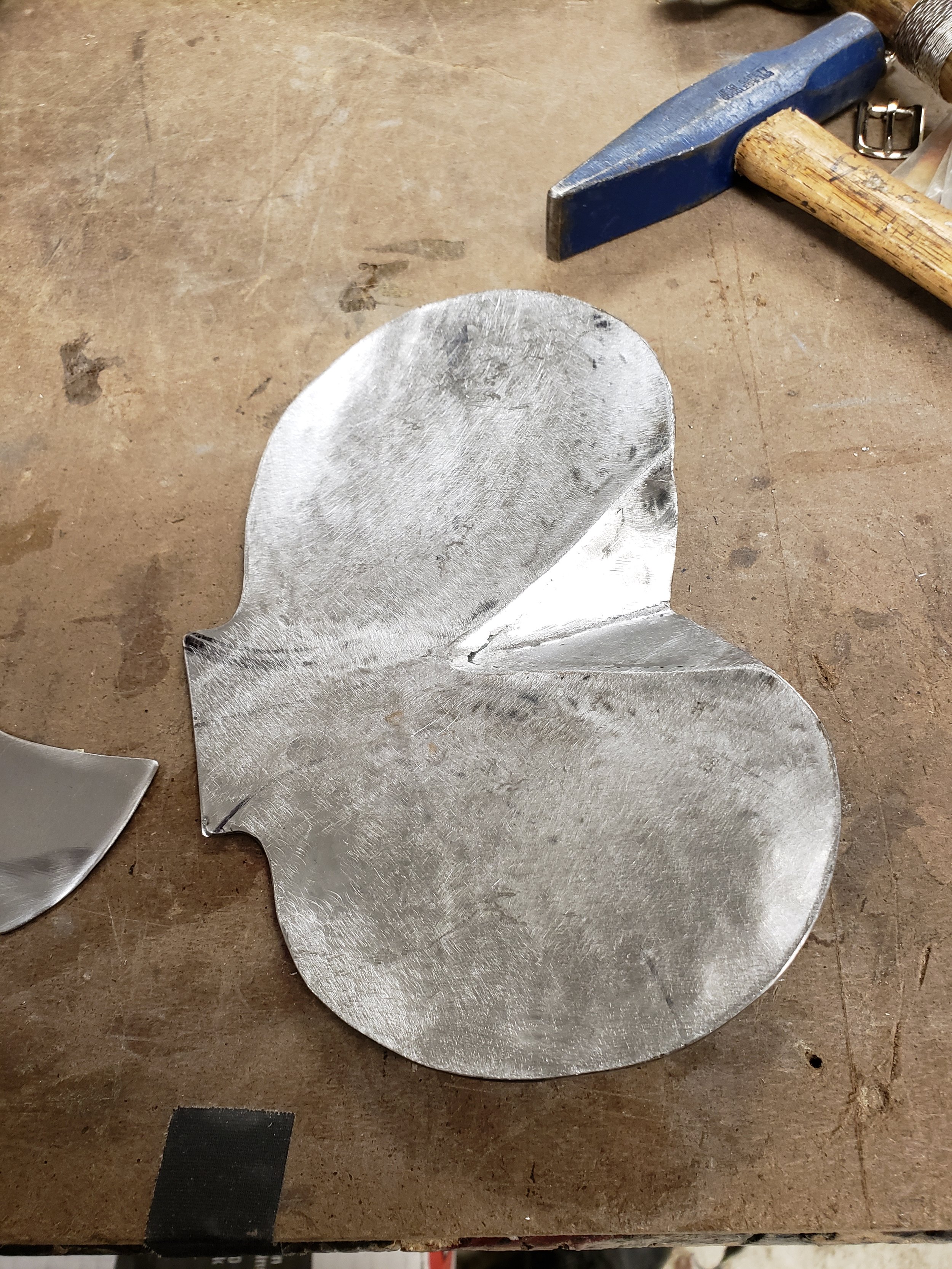

Using a pattern reference from an old HEMA pamphlet, I sized and redrew the basic structure of a cuisse to fit my leg.I cut the knee cop out of 12-gauge steel and then dished into a stump by hand before planishing the discrepancies out, sanding and polishing. It became clear quickly that fitting the lames into the correct articulation with the knee cop would have a trial and error period so instead of trying to fix the same piece I cut at least three extras of each section out of my leftover steel so that I had some sacrificial pieces to experiment with. It was an inspiring challenge to get each piece to articulate smoothly with the addition of another section without binding or gapping. The thigh guard I cut from 16-gauge steel and then shaped over a pipe to get the long compound curves of my leg. I then planished, sanded and polished each piece of the armor before moving on to the decorative pieces. I drew and cut out the exterior fin of steel, then cut and bent a small separate triangle to give it the “buckle” at the outside center edge which I welded in and cleaned to look seamless. I dished the whole piece slightly to give it extra support and style, then tacked it to the exterior edge of the knee cop and welded it in place. The decorative piece is laid on top and welded from holes in the base to lend extra strength to the joint between the base fin and knee cop. The flair around the edge is bent and welded steel rod.